Lanham's E-Ship & E-Receive supply chain solutions are now combined into one robust extension for Microsoft Dynamics 365 Business Central running across BC Online, On Premises, and Subscription licenses. You can elect to use whichever of the extension's features (modules) work best for you.

The shipping features support more efficient shipping processes whether you deal with high or low volume shipping. Popular package carriers are available as standalone extensions to make upgrades separate and easier, enabling you to enhance a package carrier without upgrading all carriers or the base E-Ship & E-Receive extension.

The receiving features in this extension bring extreme convenience and efficiency to recording incoming inventory attributes like weight and dimensions. Capturing this information in Business Central during the receiving process makes shipping even easier, particularly when you are drop-shipping items to consumers, or repeatedly shipping the same items.

E-Receive functions also make it very simple to begin automating your warehouse by adding barcodes to items as you receive them.

Be sure to explore the many functions available to support your shipping and receiving needs.

Enhance Your Shipping Accuracy

E-Ship is now an important component of the E-Ship & E-Receive extension. E-Ship users report that their shipping accuracy is consistently 100%. Using E-Ship, built inside Dynamics 365 Business Central, you can reduce costs while significantly increasing both efficiency and accuracy.

The following shipping features are modules available in E-Ship & E-Receive:

E-Ship Packing

E-Ship Packing offers two main methods of packing and shipping:

Pack Line Scanning

E-Ship & E-Receive’s differentiator is its pack line scanning capability to drive the ultimate in accuracy and efficiency. This method is used when the shipper is working with items that have barcodes on them. In addition to product barcodes, the shipper also normally uses a barcode command short cut list for scanning common commands and shortcutting keyboard strokes.

Scanned items are packed into a box while the order is visible on a packing station. If there are any items on the order not scanned into the box, a message will be displayed so that discrepancies are dealt with at that point in the process. The items can be weighed or scanned for dimensions at the time of packing as needed, and the correct label associated to the package prints as the order is closed. Detailed information for packing slips, Bills of Lading (BOLs), or EDI Advanced Ship Notices (ASNs) are also available as needed.

Fast Pack

For users that do not have barcodes on their products, Fast Pack enables the shipper to enter a quantity for each item shipped, close the package, and print the appropriate shipping label. All of the information – from customer, to shipping, to item – is housed inside the user’s Business Central system, and anything on the order not packed will be flagged so it can be handled with the customer placing the order.

Scales Interface

The Scales Interface feature enables E-Ship & E-Receive to capture weight and/or dimensions on the receiving line. In this scenario, a scale and/or dimensional scanner is integrated into the shipping line and the Scales Interface feature synchronizes it to the receiving and/or shipping software.

Users can verify the right items are packed in a given shipment based on their weight. Using a dimensional scanner will enable the shipper to accurately capture the height, width, and depth of the package to calculate accurate charges during the shipping process.

If the dimensions are entered in during the receiving process, the item’s dim/weight will be available as the order is accepted from the customer, allowing you to rate shop for the least expensive method of shipping.

Rate Shopping

This feature enables the user to estimate and quote the shipping rates at the time of sales order or the Bill of Lading for package and LTL carriers.

Bill of Lading

This feature provides shipment planning, rating and printed (Bills of Lading) BOLs.

When using Lanham EDI, please see BOL/ASN functionality in the Lanham EDI extension, this feature is enhanced to provide package detail capture to build accurate EDI Advanced Ship Notices (ASNs) during the shipping process. ASNs are automatically sent to the EDI trade partner at the time of shipping to avoid any penalties surrounding NOT receiving ASNs prior to receiving the actual product shipment. See Lanham EDI for more detail.

Label Formatter

This feature provides the ability to format customized labels and assign them to shipping agents, customers, or ship-to addresses.

LTL Shipping

This feature addresses shipping via LTL (Less Than Truckload) carriers. It enables users to import requested rate files for their account from the various shipping agents. It also accommodates the import of SMC3 Czarlite rate files if needed.

Generic Carrier

The Generic Carrier feature provides the structural framework to build out a custom package carrier. As a tool, it enables a seasoned Business Central developer to integrate a custom carrier into the E-Ship & E-Receive product.

The Email feature provides the ability to map customized email formats and assign them to customers or ship-to addresses. It is used to automatically generate detailed emails in conjunction with releasing a shipment, and may also be used to send emails to large numbers of people at one time such as when sending invoices to customers via email.

E-Ship is complemented by the following package carrier extensions:

Shipping Productivity:

- Provides two packing options for so you can choose your most efficient process

- Captures package-level detail using Packing for near 100% accuracy

- Captures serial numbers and lot numbers during packing

- Supports popular package carriers and LTL carriers

- Provides rate shopping at the time of sales order

- Enables quotation of shipping charges while taking an order

- Shipping charges can be marked up or down by $ or % and are automatically posted to the sales order

- Uses all customer and product information from Business Central

- Drives efficiency through shortcut barcode commands

- Ensures accuracy by scanning items while packing against the sales order or pick documents

- Captures item weight via scales or dim/weight via dimensional scanners

- Automatically sends tracking numbers/package content emails to customers during shipping, and stores info in Business Central

- Tracks packages and shipments from within Business Central

- Automatically creates packing lists when needed

- Automatically generates Bills of Lading

- Prints custom labels, carrier labels, GS1-128 (UCC-128) and 2D labels during shipping

- COD charges are triggered by payment terms for each sales order

- Provides reconciliation of shipping invoices

- Greatly reduces labor for shipping process

- See current E-Ship hardware requirements

- Available in Microsoft extension technology for easy upgrades

- Specifically designed to work with other Lanham Supply Chain Solutions so you can start anywhere and grow according to your business needs

Key benefits:

- Streamlines the shipping process – high or low volume

- Supports popular package carriers

(UPS, FedEx, USPS, LTL) - Automatically posts shipping charges to sales order

(mark up by % or $)

- Increases shipping accuracy

- Provides Custom Label Formatter

- Generates BOLs

- Operates warehouses and shipping points in multiple locations from a consolidated ERP system

See how seamless your shipping can be!

Access Incoming Inventory Faster with E-Receive

Streamlined Workflow for the Inbound Receiving Process

Reduce costs while significantly increasing both efficiency and accuracy.

The following receiving features are modules available in E-Ship & E-Receive:

E-Receive

The E-Receive feature automates your receiving process. At the time of receipt, items are added to Business Central before being putaway. If needed, E-Receive can add barcode scanning support to your receiving area. You can use manufacturers’ barcodes to track inventory or E-Receive generates barcodes for items, recording their characteristics in your system, and making it simple to begin barcoding in your warehouse as items are received.

E-Receive automatically updates business system functions such as receipts against purchase orders, returns, transfers, purchase invoices, credit memos and on-hand inventory. This solution enables you to log incoming inventory in your business system, allowing you to put it away more efficiently, while making it available for sale much more quickly.

Scales Interface

The Scales Interface feature enables E-Ship & E-Receive to capture weight and/or dimensions on the receiving line. In this scenario, a scale and/or dimensional scanner is integrated into the shipping line and the Scales Interface feature synchronizes it to the receiving and/or shipping software.

Users can verify the right items are packed in a given shipment based on their weight. Using a dimensional scanner will enable the shipper to accurately capture the height, width, and depth of the package to calculate accurate charges during the shipping process.

If the dimensions are entered in during the receiving process, the item’s dim/weight will be available as the order is accepted from the customer, allowing you to rate shop for the least expensive method of shipping.

Label Formatter

This feature, when used in the receiving process, provides the ability to format barcodes and customized labels. The labels can be used for inventory items or any custom label requirement.

Achieve Receiving Proficiency:

- Enables receiving against PO’s, sales returns, transfers, purchase invoices, and sales credit memos

- Flags under or over receiving for accounting approval

- Updates item cards in your system when most effective, during the receiving process

- Enables product attribute capture and barcoding

- Embeds lot and serial numbers in barcodes printed during receiving

- Provides for use of vendor bar codes or assignment of unique bar codes during receiving

- Enables creation of cross references for real time updating of Cross Reference Table (used when vendor changes bar code or a new unit of measure is added)

- Saves time by using reduced-interaction cloud printing

- See current E-Receive hardware requirements

- Available in Microsoft extension technology for easy upgrades

- Specifically designed to work with other Lanham Supply Chain Solutions so you can start anywhere and grow according to your business needs

Know when you have inventory on hand. Gain a better understanding of what is coming in and going out while tremendously increasing efficiency.

Key benefits:

- Captures product attributes during receiving

- Enables bar coding during receiving

- Supports all inbound trade documents (POs, returns, transfers, purchase invoices, credit memos)

- Permits over-receiving with flags to accounting

- Let E-Receive help you gain a better understanding of what is coming in and going out while drastically increasing efficiency.

Refine your Receiving Right Now!

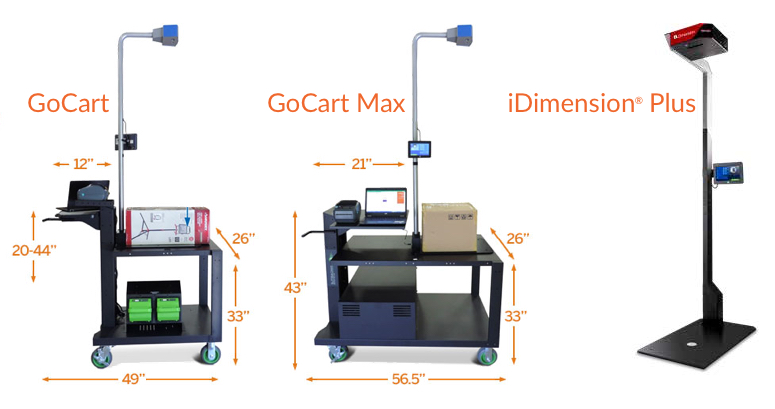

Hardware requirements E-Ship & E-Receive Extension:

A wide variety of hardware from Cisco, Honeywell, HP-Aruba, Newcastle, Rice Lake, Mettler Toledo and Zebra Technologies that seamlessly integrate with E-Ship & E-Receive include:

- Tethered or Untethered Scanners

- Bin Location Labeling and Signage

- Industrial, Tabletop, and Portable Printers

- Powered Mobile Carts

- Scales & Box Dimensioners

Barcom, Inc., phone (423) 855-1822. Click here for more details.

iDimension® Options: