Based on 20+ years of experience in warehouse management, ACE Warehousing is designed to work in a tightly cooperative manner with Microsoft Dynamics 365 Business Central Advanced Warehousing, and the Lanham E-Ship and E-Receive and OWR (Outbound Warehouse Request) extensions to optimize processes in the warehouse.

ACE Warehousing stores all of your supply chain data securely inside your ERP system, and provides many options for organizing your warehouse with real-time inventory control.

ACE Warehousing provides many options for organizing your warehouse with real-time inventory control. The solution meets you where you are today – whether your warehouse operates with or without paper.

ACE Warehousing supports lot and serial number tracking through Business Central Advanced Warehousing, as well as Bins, Directed Pick, Directed Putaway, Shipments and Receipts. The solution may be further enhanced with Lanham E-Ship and E-Receive and OWR (Outbound Warehouse Request) capabilities for shipping receiving, and shipment scheduling as needed.

ACE Warehousing handles comprehensive WMS transactions, including those associated with receiving and production. This enables users to receive goods, or capture and post production consumption, as well as production output, via the handheld devices.

Further, the solution enables planned cycle counting. Dynamic physical inventory capabilities, sometimes known as ad-hoc counts, can also be enabled so that these activities can take place without disrupting other warehouse processes.

ACE Warehousing will help you formalize the structure around controlling your inventory while minimizing complexity.

The following features are available in Lanham ACE Warehousing:

Warehouse Basic

ACE Warehousing Basic allows a variety of functionality from a mobile device. This includes supporting Business Central’s item tracking, as well as executing, updating, and registering pick, put-away, movement, and physical inventory transactions. It also allows visibility to Business Central bin content records.

Warehouse Dynamic

Warehouse Dynamic extends ACE Warehousing Basic, allowing users to dynamically create put-away, movement, and physical inventory transactions, as well as execute or register them ad-hoc from a handheld device.

Warehouse Pick/Pack (E-Ship)

This feature enables users to pack while picking, by capturing package or pallet detail during the pick. A link to E-Ship Pack Line Scanning transfers package detail for more efficient processing, enabling paperless warehousing.

Warehouse Extended Features

Warehouse Extended Features provides license plate functionality, including adjustments, movements, moving items between license plates, physical inventory of license plates, and picking of and from license plates.

The feature’s bin count functionality is an enhancement to the Business Central Warehouse Physical Inventory Journal counting process. It enables users to perform physical inventory while other warehousing activities are taking place, without freezing inventory.

Warehouse Data Capture

Warehouse Data Capture enables wireless receiving, allowing users to receive against purchase, sales returns, and transfer orders with mobile handheld devices.

This feature also handles production transactions. It enables users to capture and post consumption for production orders from handheld devices. Its wireless output capture functionality also enables users to post production output directly from the handheld devices.

Print Queue

Print Queue is designed to minimize human intervention for printing and to streamline the cloud printing process, making it simple and straightforward. This feature provides the ability to assign printers in various locations in the warehouse to processes that print barcodes, labels, and reports via web services.

Lanham ACE Warehousing drives increased efficiency:

- Handheld interface is streamlined and simple

- Provides real-time data access, so inventory is 100% up-to-date at all times

- Supplies extensive validation, confirming bins and items every step of the way to drastically reduce mistakes

- Simple to sophisticated functionality enables companies to start anywhere and grow as their requirements evolve

- Integrates with the warehousing features in Business Central Advanced Warehousing, Lanham E-Ship and E-Receive and/or OWR for enhanced warehouse order fulfillment operations

- Supports multiple pick options

- Handles License Plating

- Provides Receiving via mobile handheld devices

- Offers Planned Cycle Counting or ad-hoc Dynamic Physical Inventory

- Supports Production – captures consumption, and posts production output

Key benefits:

- Comprehensive WMS, as simple or complex as you need

- Real-time inventory

- Validation that drastically reduces mistakes

- Licensing plating

- Dynamic physical inventory without freezing operations

- Designed to work with all Lanham solutions so you can start anywhere and grow with your business needs

Explore the advantages of ACE Warehousing

Hardware requirements for ACE Warehousing Extension:

A wide variety of data collection, WIFI and mobile devices from Cisco, Honeywell, HP-Aruba, Newcastle, Rice Lake and Zebra Technologies that seamlessly integrate with ACE Warehousing include:

- Handheld & Wearable Computers

- Vehicle-Mount Computers

- RF Infrastructure – Wireless Warehouse Network

- Bin Location Labeling and Signage

- Industrial, Tabletop, and Portable Printers

- Powered Mobile Carts

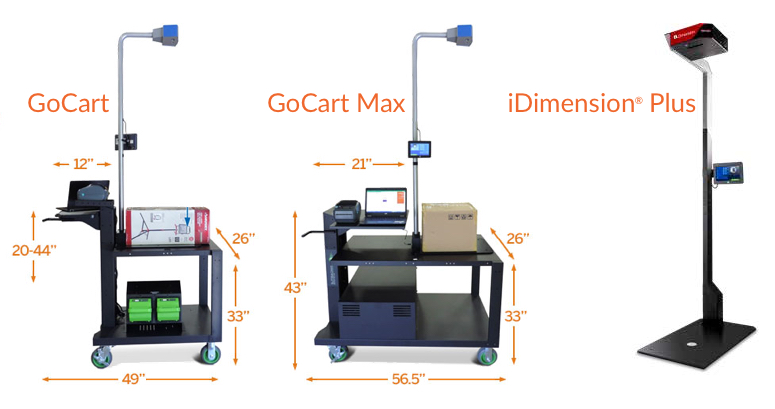

- Scales & Box Dimensioners

Detailed configuration options can be obtained through our national hardware supplier,

Detailed configuration options can be obtained through our national hardware supplier,

Barcom, Inc., phone (423) 855-1822.

Newer Hardware Options: