4 Core Strategies for Demand Planning in the Time of COVID-19

Posted on July 28, 2020By Erik Beissel, Demand Planning Consultant, The Lanham Companies

Not only has the Coronavirus resulted in varying symptoms in those unfortunate enough to have become infected, but it is also affecting companies’ inventories and the entire supply chain in many different ways. From our Demand Planning consulting vantage point across Lanham Associates and Absolute Value, it is clear that when you look at the ramifications of the pandemic on inventory management, every company has been affected in some way. However, no one scenario applies to all areas or all businesses.

Over the last few months, a number of clients have experienced large decreases in sales in all items and locations, or just in specific locations or product groups. Others have experienced the exact opposite and have large increases. One extreme example of this is a client that had all of its retail locations closed for over two months because of government restrictions, and at the same time they experienced a 300% increase in their e-commerce orders.

For the majority of clients, the impact has been less extreme — more of a general decrease in sales, with high consumer demand on specific items or item categories. Almost all have had large increases in alternate items when standard items are out of stock and unavailable from suppliers.

From an inventory management perspective, in these types of conditions it is necessary to be on the alert and ready to adjust lead times, history, forecasts, and more. While we do not have a COVID-19 solution that will eliminate the virus’ impact on your business, we have identified four “core response options” which the majority of our clients are using to meet the demand planning challenges caused by the impact the COVID-19 pandemic has had on the supply chain.

Four Core Response Options

In the interest of knowledge-sharing during these difficult times, this post is geared towards Demand Planning users. It’s important to note that no two companies have identical needs and these four core response options are not the only features available in our Demand Planning solution to cope with the effects of COVID-19 or to deal with the historical usage accuracy issue. But they are the four approaches that have applied to the majority of clients we have worked with since the start of the pandemic. If you’d like to explore other options for your specific situation, we’re here to help.

1. Adjustment of the forecast

There are two ways to execute this:

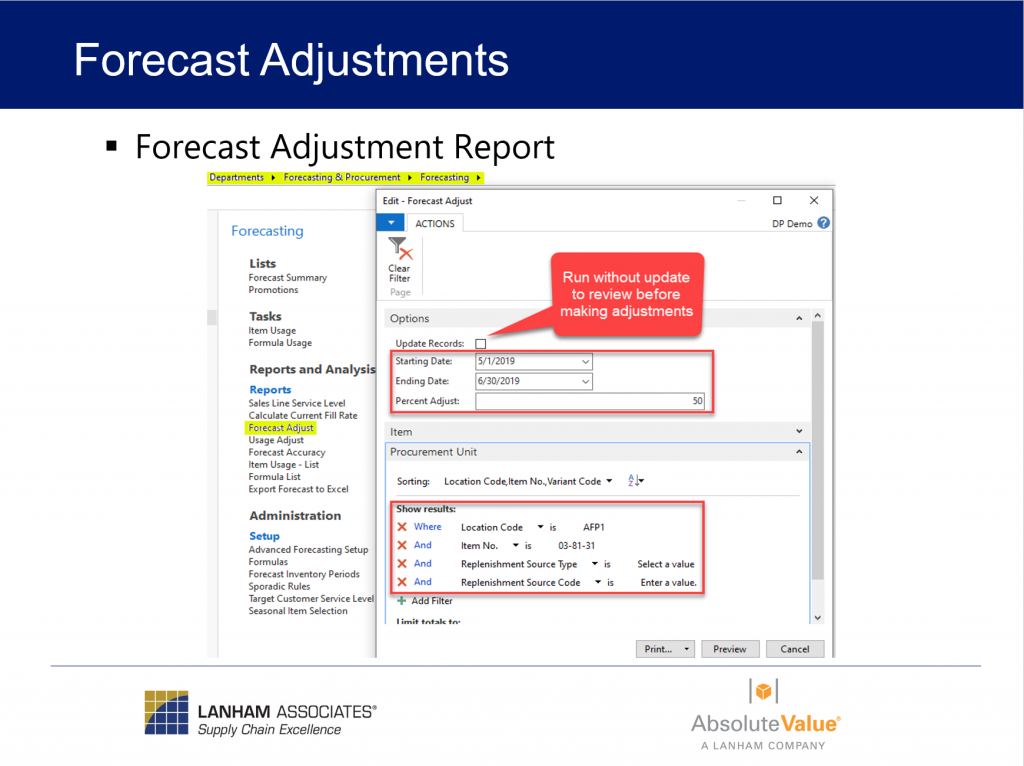

a.) Broad-based changes by percentage with the Forecast Adjust report.

Demand Planning’s Forecast Adjustment report can be run without updates so users are able to view the changes prior to applying them to the system. Then it’s a simple matter of selecting the periods you want to adjust the forecast, and determining the percentage of adjustment to apply.

The adjustment percentage can be either positive or negative. The Forecast Adjustment report allows filtering by base Business Central/NAV item values or procurement unit values, enabling you to apply different adjustments based upon locations, product groups, or replenishment types.

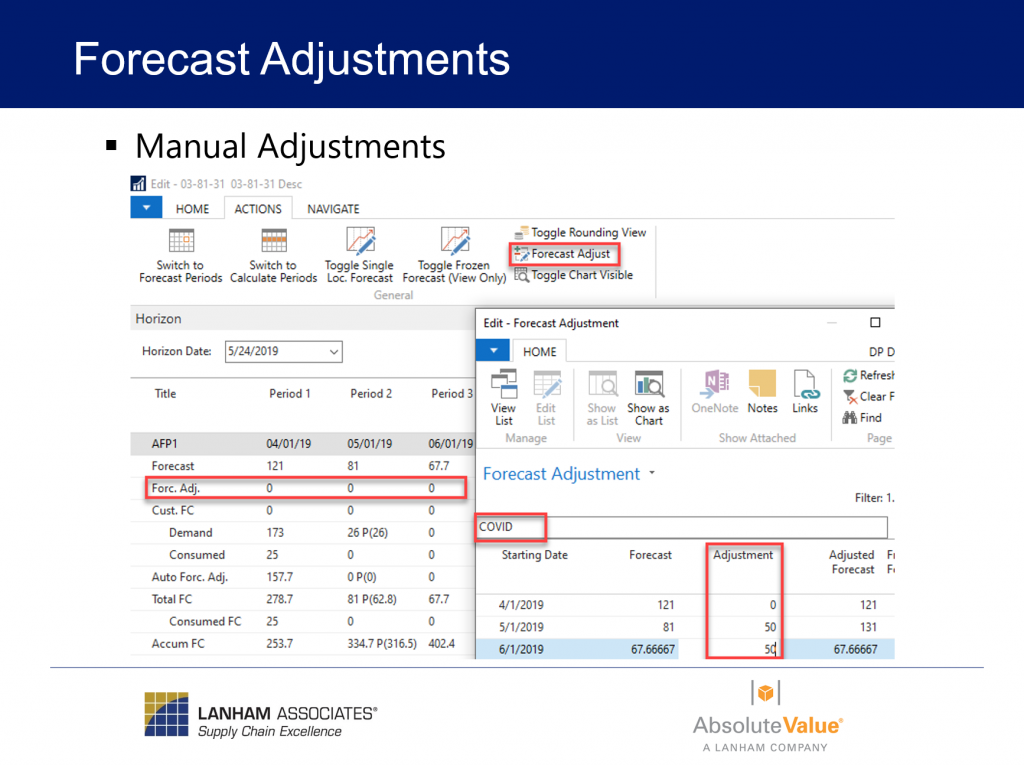

b.) Making focused, manual adjustments on specific items or item groups that are exceptions to the broad-based changes.

When the manual adjustments have been entered you can select the cell with the adjustment, exposing an ellipse, and then drill down to see the adjustment note. You’ll be able to see the day it was adjusted and the user that made the adjustment. From this point, the forecast adjustment can be updated or even deleted – in the event it no longer applies.

Is Historical Usage the Right History?

Creating a statistical forecast based on your company’s historical usage is a key pillar of Demand Planning. However, due to the broad and significant COVID-19 related ramifications across the entire supply chain, this can be problematic.

The crux of the problem is that when we look ahead to when the impact of COVID-19 has significantly decreased or been eliminated, the historical usage recorded in the months impacted by the pandemic will be generating a forecast that does not necessarily match “normal demand.”

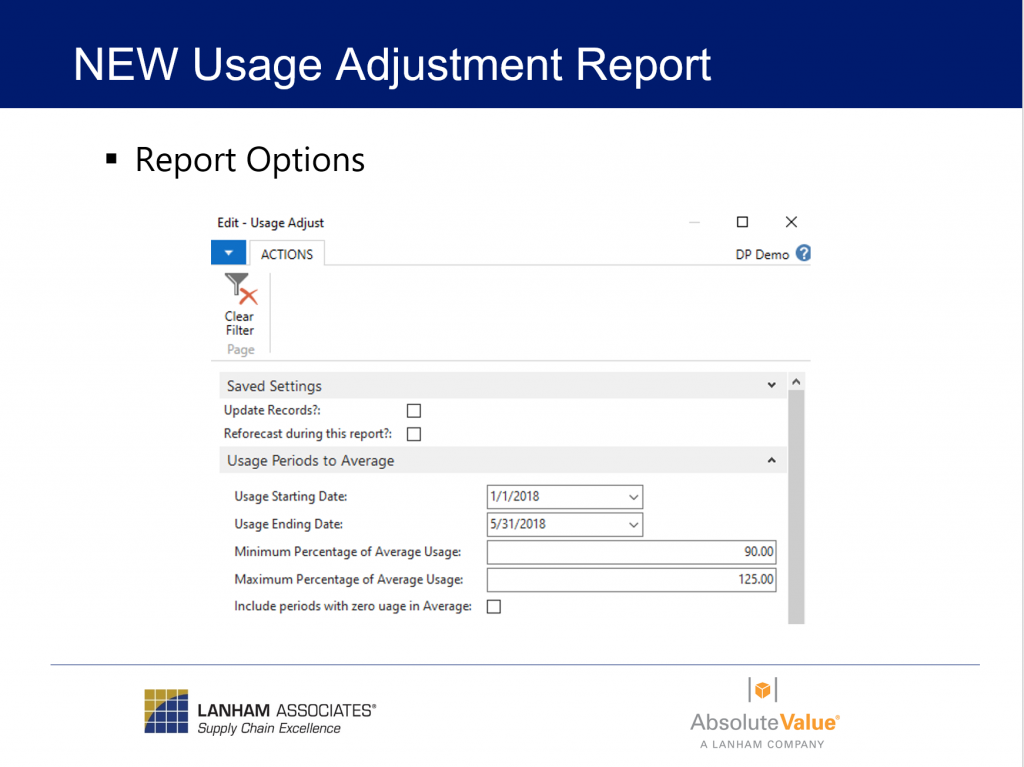

It goes without saying that historical usage is critical when it comes to creating your statistical forecast. However, the current process of manual usage adjustments or using the item usage review batch to review manually and adjust unusual usage is not efficient in the current conditions. Consequently, our development team created a new Usage Adjustment report which allows users to mathematically adjust usage, based on user-designated parameters.

2. Adjusting the Usage

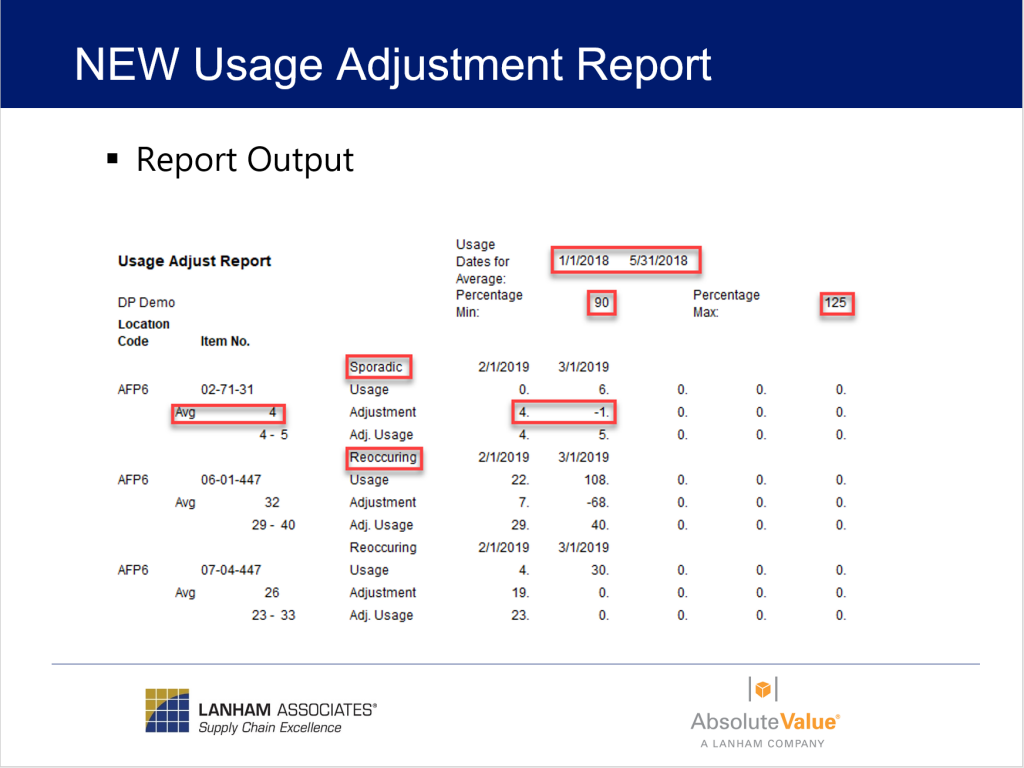

The new Usage Adjustment report works by the user selecting the range of historical periods to create an average, and then setting a percentage minimum and maximum parameter. If actual usage is below the minimum percentage, a positive usage adjustment is created. If actual usage exceeds the maximum percentage, a negative usage adjustment is created to normalize the usage.

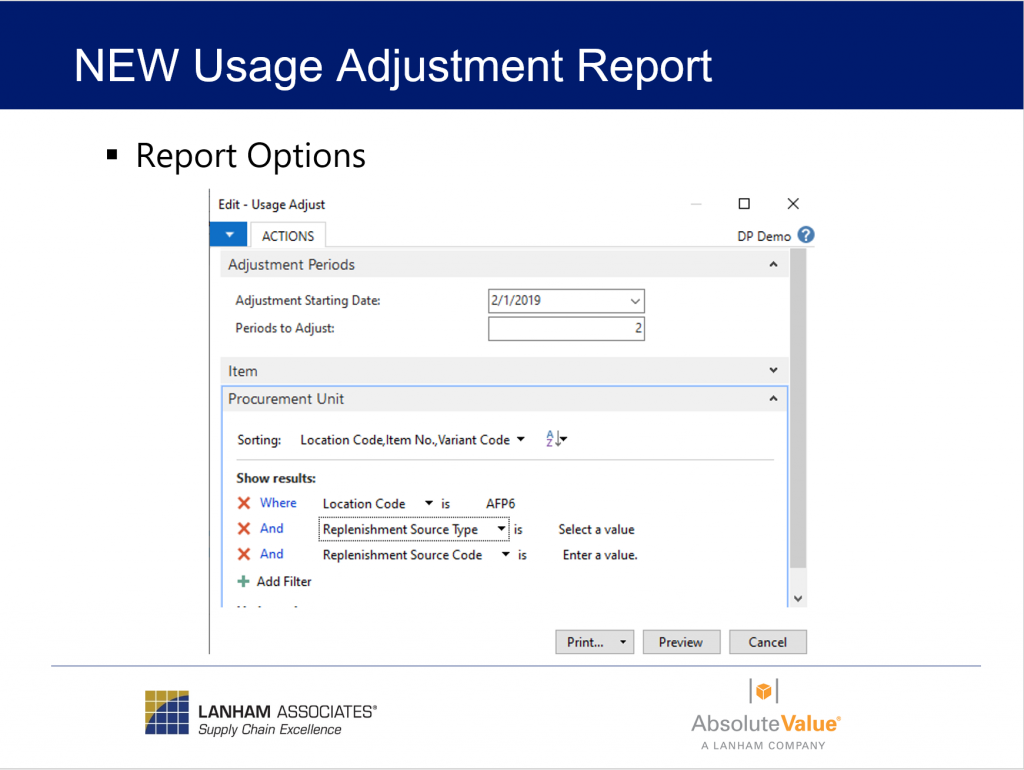

Next, select the periods to be adjusted. In this example the first period is February and it will use the average calculated to adjust two periods so February and March will be adjusted. The Usage Adjustment report allows filtering by base Business Central/NAV item values or procurement unit values, enabling you to apply different adjustments based upon locations, product groups, or replenishment types.

Viewing the report output, all of the settings used to create the usage adjustment are recorded along with the adjustments made to your historical usage.

3. Utilize the Alert Worksheet

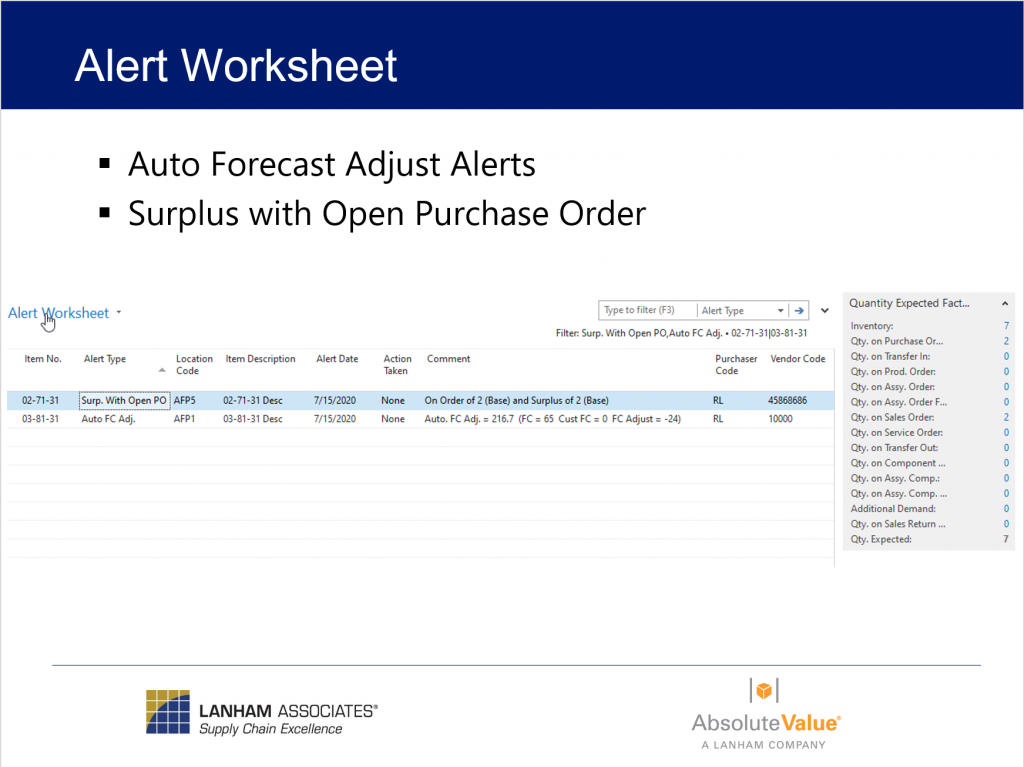

Demand Planning enables management by exception through the use of alerts that notify users of situations before they become problems.

During the COVID-19 pandemic, our clients are focusing on the Auto Forecast Adjust and the Surplus with Open Purchase Order alerts.

a.) Auto Forecast Adjust Alert: Demand Planning software immediately recognizes when demand exceeds the forecast, and creates an auto forecast adjustment. The alert is then created during the overnight process. Your procurement team can then review the demand, usage, and forecast for these items.

b.) Surplus with Open Purchase Order Alert: After forecast adjustments have been entered the overnight process will recalculate surplus based upon the new forecast. If there are any items that now have surplus or excess inventory, and there are open purchase order lines, an alert will be created allowing you the opportunity to contact your vendors to cancel or reschedule delivery of these now unnecessary items.

4. Update the vendor buying calendar and procurement unit frozen vendor lead times

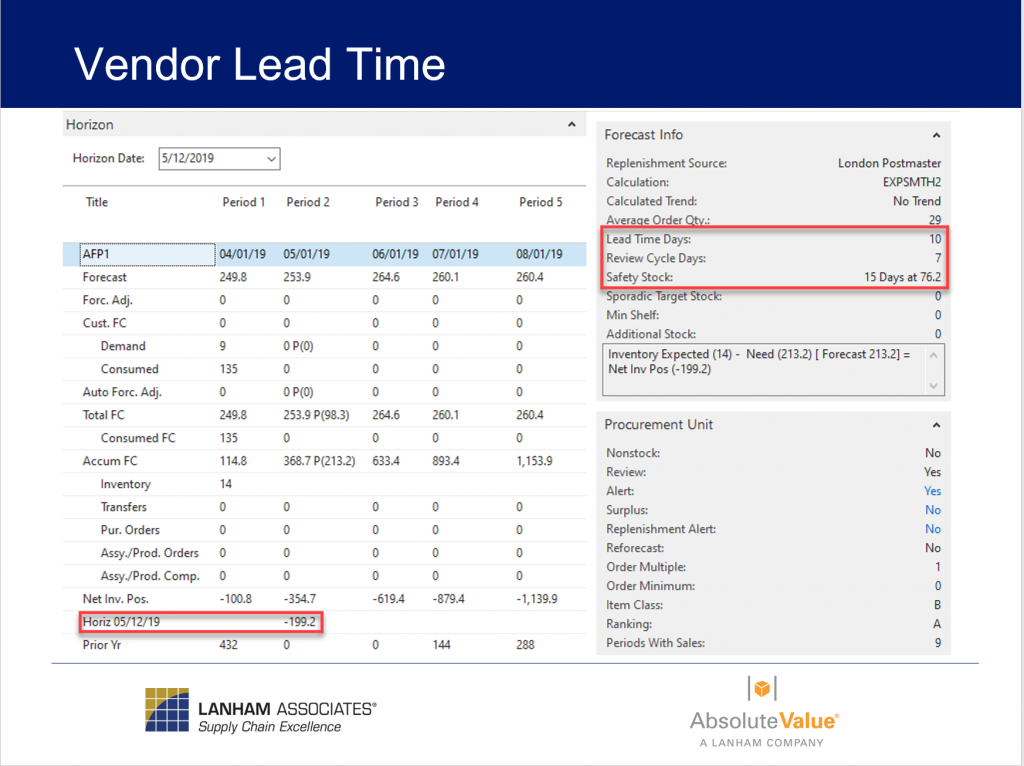

The vendor lead time is a critical component in the calculations of the quantity needed on a suggested purchase order.

Given the current disruptions in the supply chain, an average based on past performance is probably no longer accurate for planning purposes. If your company is using a calculated lead time, we recommend utilizing the vendor buying calendar frozen lead-time days, and the procurement unit frozen lead time days. This allows your procurement department to take positive control of the planning horizon being used instead of relying on historical vendor performance data that is incorrect.

In Summary

Here’s a quick overview of the four core response options which are working for the majority of our clients:

- At the beginning of the period, utilize the usage adjust report to normalize the last closed period usage.

- Allow the system to re-forecast overnight.

- Utilize the Forecast Adjust report to make broad-based Forecast Adjustments to account for the impact of COVID-19 on your company’s operations.

- Make Manual Forecast Adjustments on items that are exceptions to the broad-based trend.

- Review surplus with open PO alerts for purchase order line items that should be rescheduled or canceled.

- Closely monitor Auto Forecast Adjust alerts for items that have exceeded the current forecast and make adjustments as necessary.

- Lastly, closely monitor vendor confirmations and delivery trends to ensure you’re using the most accurate vendor lead times based upon current vendor performance.

For existing clients — if you’d like more details about the options outlined here, or would like to discuss your current system settings with a Demand Planning consultant. Please email us at Support@lanhamassoc.com.

If you are interested in learning more about our Lanham Demand Planning product, please email us at LAInfo@lanhamassoc.com to request additional information or to schedule a demo. For information, or a demo of the Absolute Value Demand Planning solution, click here.

The world may be upside down at the moment, but your inventory doesn’t have to be.

+++